| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | APBWR |

| Model Number : | SLW54 |

| Certification : | ISO9001 |

| Price : | $5000-50000 |

| Payment Terms : | L/C,T/T |

| Supply Ability : | 1000+ /year |

| Delivery Time : | 14-21DAYS |

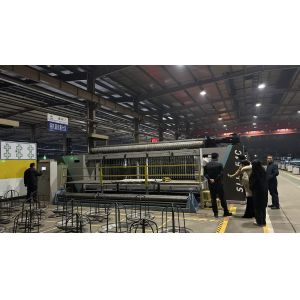

Multi Functional Auto Gabion Mesh Machine Quick Setup SLW54

1.Gabion Mesh Machine Key Components

◦Precise weaving technology: Employing a hexagonal double-twisted weaving technique, the metal wire twisting force and angle are precisely controlled by machinery to ensure uniform mesh holes in the shape of regular hexagons. This results in a stable structure with even stress distribution, effectively preventing local breakage.

◦ Flexible specification adjustment: Parameters such as mesh hole size, wire diameter, mesh width, and length can be flexibly adjusted according to different engineering requirements.

◦ High degree of automation: Typically equipped with a CNC control system, it can automate production processes including wire feeding, weaving, winding, and wire breaking. Operators only need to set parameters on the console, allowing the equipment to run continuously, reducing manual intervention and improving production efficiency and product quality stability.

◦ Strong material compatibility: It can process various types of metal wires such as low-carbon steel wire, galvanized steel wire, and PVC/PE-coated steel wire, meeting different engineering requirements for corrosion resistance and durability. For example, ordinary low-carbon steel wire is suitable for temporary protection, while PVC/PE-coated steel wire is applicable in coastal areas, high-saline and alkaline regions, etc.

◦ Safe and convenient operation: Adopting a closed operation design, it isolates dangerous links from operators and is equipped with safety devices such as overload protection and wire breaking alarms to reduce the risk of work-related injuries. Additionally, the operation interface is simple, and ordinary workers can start operating after simple training.

2. Gabion Mesh Machine Production Assurance

Our fully automated CNC gabion machine is equipped with intelligent remote maintenance systems, providing:

Remote diagnostics for precise issue identification

Quick problem resolution through remote adjustments and guided repairs.

Reduced operational costs and enhanced productivity with minimal downtime.

Data-driven management for optimized performance and long-term efficiency.

These advantages cater to clients' needs for flexibility, cost-effectiveness, and production stability.

3.Basic Model Specification Of Gabion Mesh Machine

Parameter | Specification | Description |

Weaving Width | 5200 mm | Standard effective weaving width |

Wire Diameter Range | 1.5–4.5 mm (varies by spec) | Varies depending on weaving range and specification |

Mesh Size Specification | 6.6, 6.8, 7, 7.2, 8.4, 8.6, 8.8, 9, 9.2, 9.4, 10.2, 10.6, 11.6 mm | Customizable to meet various gabion requirements |

Twisting Method | 3 twists, 5 twists, long or short pitch | Available in 3-twist, 5-twist, long or short twist patterns |

Operating Speed | Approx. 70 cycles/min | Actual speed varies based on mesh width and wire diameter |

Maximum Output | 320 m/hour | Theoretical maximum output, varies with operating conditions |

Motor Power | 15 KW × 1, 11 KW × 4 | 1 main motor and 4 auxiliary motors |

Auto Pause System | ✔ Yes / □ No | Stops automatically in case of fault or wire breakage |

Auto Lubrication System | ✔ Yes / □ No | Automatic lubrication to reduce maintenance needs |

Boundary Dimension | 9.79 × 1.40 × 3.07 m | Length × Width × Height |

Net Weight | 18.5 tons | Net weight (excluding packaging) |

CNC System | Self-developed electronic cam system | Customizable based on customer requirements |

4. Introduction to Gabion Mesh Machine Auxiliary Equipment

Equipment Name | Equipment Model | Function Description |

Cutting Machine | BWR-JW40A | Precisely cuts woven gabion mesh to specified sizes, ensuring accurate cut positions and neat edges; suitable for fixed-length cutting of various gabion specifications. |

Curling Machine | BWR-JB40A | Performs edge curling to enhance strength and stability, preventing wire loosening or scratching; facilitates splicing and fixing during installation. |

Spring Machine | BWR-JHB13B | Produces spring tubes with consistent specifications to match the mesh body, improving overall structural stability of gabion mesh. |

5.Detailed images:

|