| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | APBWR |

| Model Number : | SLW-54C |

| Certification : | ISO9001 |

| Price : | $5000-50000 |

| Payment Terms : | L/C,T/T |

| Supply Ability : | 1000+ /year |

| Delivery Time : | 14-21DAYS |

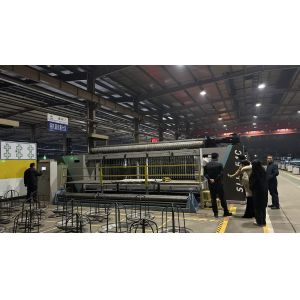

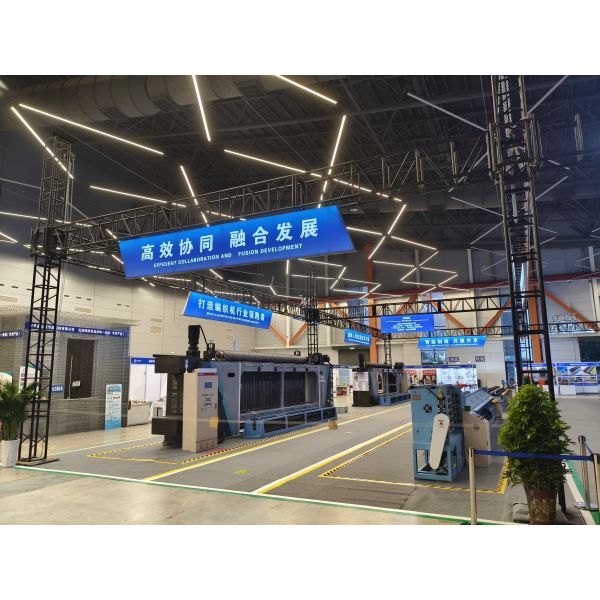

Stable Performance Automatic Gabion Mesh Machine High Precision SLW-54C

1.Gabion Machine Key Components:

Uncoils and straightens steel wire (typically galvanized or PVC-coated).Forms mesh through welding or weaving, tailored to gabion specifications.Precision-cut wires or mesh panels using hydraulic or pneumatic tools. User-friendly CNC interface for programming dimensions, mesh patterns, and production speed.Some machines fold and assemble mesh into 3D boxes, while others produce flat panels for later assembly.

At our loacl area, there are many raw material manufacturers and we keep good relationship with them, we have large and stable purchase quantity from them and they guarantee to supply stable quality material to us. They arranged a person who only responsible for our material's production and delivery to make sure safe quality.

2.Gabion Machine Working Process:

Wire Preparation: Wires are fed, straightened, and cut to required lengths.

Mesh Creation: Wires are welded or woven into hexagonal or rectangular grids.

Cutting & Shaping: Panels are cut to size, with edges shaped for assembly.

Automated Assembly: Panels are folded into box structures, with spiral connectors or rings added for stability.

3.Gabion Machine Technical Specifications:

Wire Diameter: 1.5-4.5mm.

Mesh Sizes: Adjustable (e.g., 60x80 mm to 130x160 mm).

Production Speed: Up 60 times per minute (producing 30 meshes), depending on the model and complexity of the product.

Power Requirements: The machine is driven by five servo motors, including four 11kw motors and one 15kw motor.

4.Basic Model Specification Of Gabion Mesh Machine

Parameter | Specification | Description |

Weaving Width | 5200 mm | Standard effective weaving width |

Wire Diameter Range | 1.5–4.5 mm (varies by spec) | Varies depending on weaving range and specification |

Mesh Size Specification | 6.6, 6.8, 7, 7.2, 8.4, 8.6, 8.8, 9, 9.2, 9.4, 10.2, 10.6, 11.6 mm | Customizable to meet various gabion requirements |

Twisting Method | 3 twists, 5 twists, long or short pitch | Available in 3-twist, 5-twist, long or short twist patterns |

Operating Speed | Approx. 70 cycles/min | Actual speed varies based on mesh width and wire diameter |

Maximum Output | 320 m/hour | Theoretical maximum output, varies with operating conditions |

Motor Power | 15 KW × 1, 11 KW × 4 | 1 main motor and 4 auxiliary motors |

Auto Pause System | ✔ Yes / □ No | Stops automatically in case of fault or wire breakage |

Auto Lubrication System | ✔ Yes / □ No | Automatic lubrication to reduce maintenance needs |

Boundary Dimension | 9.79 × 1.40 × 3.07 m | Length × Width × Height |

Net Weight | 18.5 tons | Net weight (excluding packaging) |

CNC System | Self-developed electronic cam system | Customizable based on customer requirements |

4. Introduction to Gabion Mesh Machine Auxiliary Equipment

Equipment Name | Equipment Model | Function Description |

Cutting Machine | BWR-JW40A | Precisely cuts woven gabion mesh to specified sizes, ensuring accurate cut positions and neat edges; suitable for fixed-length cutting of various gabion specifications. |

Curling Machine | BWR-JB40A | Performs edge curling to enhance strength and stability, preventing wire loosening or scratching; facilitates splicing and fixing during installation. |

Spring Machine | BWR-JHB13B | Produces spring tubes with consistent specifications to match the mesh body, improving overall structural stability of gabion mesh. |

5.Detailed images:

|